Using Oil Refinery Emissions

Oil refineries have a massive carbon footprint, partly through burning hydrocarbon fuels for heat, and partly as a byproduct from the chemical reactions themselves. We propose using the carbon dioxide as a raw material alongside oil and gas to make more sustainable use of available carbon resources.

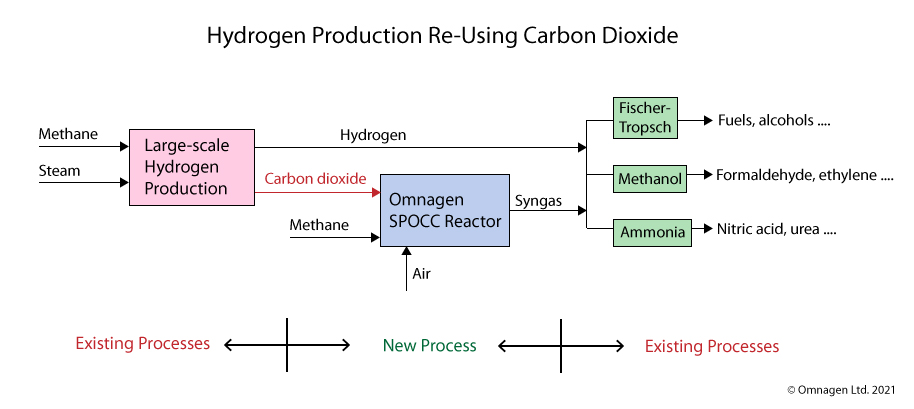

By far the largest emitter is hydrogen production from methane – either Steam Methane Reforming (SMR) or Autothermal Reforming (ATR) plus the Water Gas Shift (WGS) reaction. The products are large quantities of both hydrogen and CO2. Omnagen’s SPOCC Reactor can re-use that CO2 by reacting it with methane and air at elevated temperature: once at temperature, the reactions are self-sustaining.

This ‘grey’ hydrogen production makes a large contribution towards global CO2 emissions. It is also a wasted resource, because the chemical industry needs carbon to make its products. We propose using CO2 as well as natural gas and oil as raw materials.

The image below shows three possible production routes using the combined raw materials of hydrogen, and syngas from the SPOCC Reactor. Each route can produce a range of chemicals, and many of those can be further converted into a vast range of other chemicals:-

- Fischer-Tropsch synthesis – producing fuels, alcohols…..

- Methanol production, then – formaldehyde, acetic acid, ethylene…..

- Ammonia production by the Haber process, then – nitric acid, urea…..

'Sky Blue' Hydrogen

There is an urgent need to make existing 'grey' hydrogen production facilities more sustainable. Some favour CCS (carbon capture and storage), where the CO2 is captured, liquified and buried; this is referred to as 'blue' hydrogen. But CO2 is a valuable source of carbon, and it makes sense to re-use it rather than bury it. We use the term 'sky blue' hydrogen to describe our method for making 'grey' hydrogen sustainable.

'Green' Hydrogen

‘Green’ hydrogen is produced by water electrolysis using renewable energy. It is energy intensive, requiring about 50kWh of energy to produce a kg of hydrogen. It also uses plenty of fresh water, requiring 9kgs of water for each kg of hydrogen produced. Sea water will not do, Therefore the scale of ‘green’ hydrogen which is possible, is dependent on supplies of both renewable energy and fresh water.

SPOCC Reactor

The Self-Powered CO2 Converter combines methane, CO2 and air at elevated temperature. Once at temperature, the reactions are self-sustaining.

Take a look to see how the technology works.

Sustainable Aviation Fuel

Anaerobic digesters convert organic matter into a mixture of methane and CO2. The SPOCC Reactor can be used as part of a route to produce sustainable aviation fuel. For an explanation.

Cement Decarbonisation

Cement production is responsible for at least 5% of global carbon dioxide emissions. Where a supply of natural gas is available, we propose capturing the CO2, adding natural gas and air, and making syngas at the site. This can be further processed to valuable chemicals.