Sustainable Aviation Fuel

The SPOCC Reactor provides a route for converting biogas into synthetic fuels, with no emissions.

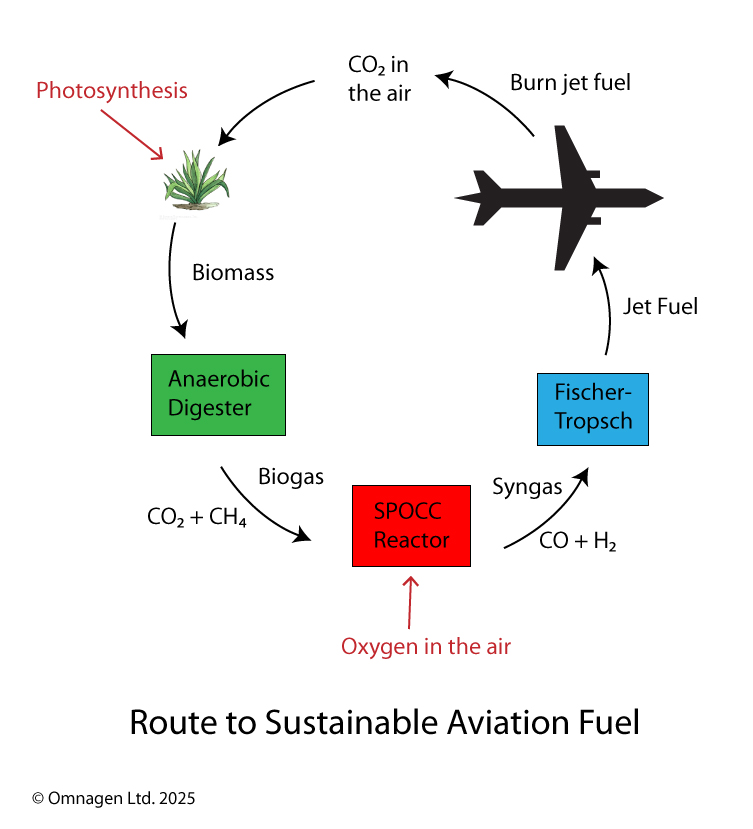

Biogas, a mixture of methane and carbon dioxide, is formed by the action of bacteria on organic matter in the absence of oxygen (known as anaerobic conditions). This is the ideal input for the SPOCC Reactor which converts it to syngas, which existing processes can convert into sustainable aviation fuel (SAF).

If waste organic matter is used as the raw material, this provides a sustainable route to the production of fuel for aviation, marine and commercial vehicles. The product has a negative carbon footprint. This would allow airports and airlines to continue using their existing infrastructure.

Despite progress in developing hydrogen-powered and electric planes, hydrocarbon fuel will be needed to power most aircraft for some time to come. The image below outlines a route for the manufacture of sustainable aviation fuel.

Energy is needed to break the carbon-oxygen bond in carbon dioxide. Reactions in the above cycle break down CO2 at 2 places.

- In plants, photosynthesis uses energy from the sun to convert CO2 into sugars, which can be used by the plant to make the organic matter it needs.

- In the SPOCC Reactor where the partial oxidation of methane at elevated temperature powers the breakdown of CO2.

SPOCC Reactor

The Self-Powered CO2 Converter combines methane, CO2 and air at elevated temperature. Once at temperature, the reactions are self-sustaining.

Take a look to see how the technology works.

Cement Decarbonisation

Cement production is responsible for at least 5% of global carbon dioxide emissions. Where a supply of natural gas is available, we propose capturing the CO2, adding natural gas and air, and making syngas at the site. This can be further processed to valuable chemicals.

Use Refinery Emissions

Oil refineries have a massive carbon footprint, partly through burning hydrocarbon fuels for heat, and partly as a byproduct from the chemical reactions themselves. We propose using the carbon dioxide as a raw material alongside oil and gas to make more sustainable use of available carbon resources.

Read how the SPOCC Reactor makes this possible.